ISO Quality Objective

| Sr.No | Objectives | Indicator | Methodology | Target | Responsibility of Maintaining data | Frequency of Maintaining data |

| 1 | To improve students satisfaction | % of SSI | To calculate students satisfaction index once in six month | More than previous SSI | Respective head of the institute | Semester's |

| 2 | To improve the proficiency of faculty | Number Of FDP Programs | To Calculate Number of FDP programs | 12 per year | FDP/Academic coordinator | Quarterly |

| 3 | To complete 100% syllabus | Monthly report of syllabus completion | To assess monthly report | 100% as Planned | Subject teachers | Semester/ Yearly |

| 4 | To maintain the attendance as per requirement | Attendance percentage | To calculate the percentage attendance | 85% | Class teachers | Monthly |

| 5 | To minimize students complaints | Number of complaints | Complaints’ Register | Less number of grievances than previous number | Grievance committee in charge | Monthly |

| 6 | To ensure efforts to show rise of 3% in results | %age students passed with distinction | To ensure the result as per target | % More than previous result % age | Acadmic incharge | Semester/Yearly |

| 7 | To ensure results are more than that of university | University result, Institute result | To ensure the result as per target | more than university result | Acadmic incharge | Semester/Yearly |

Quality management systems - Requirements

ISO 9001:2015 specifies requirements for a quality management system when an organization:

All the requirements of ISO 9001:2015 are generic and are intended to be applicable to any organization, regardless of its type or size, or the products and services it provides.

ISO 9001: Moving from ISO 9001-2008 to ISO 9001-2015

The core of this standard, and many other management system standards, is the so-called Plan-Do- Check-Act (PDCA) cycle, which says that, in order to have an effective management system. The first step in the cycle is planning, which includes defining objectives, policies, procedures, and processes, including measuring aimed to show whether the processes are delivering the expected results. The next step is the Do phase, which represents the realization of the planned arrangements, applying policies and procedures, performing processes, and producing records. After the Do phase comes the Check phase, where the results of the Do phase are analysed to determine performance and effectiveness of the activities and actions that were taken during the Do phase, which includes analysing, monitoring, and measuring results, audits, and management reviews. As the final stage of the cycle, the Act phase is where the organization needs to take actions according to the results of the Act phase in order to achieve continual improvement. The PDCA cycle should be an ongoing cycle that drives the organization towards continual improvement.

Plan – Analysis of the business environment and customer needs and their influence on the organization. Define company targets, objectives and processes to meet customer expectations.

Do – Implementation of management and quality action plans and collection of data for analysis in subsequent steps.

Check – Monitoring and measuring processes and actual results for comparison with expected results and targets.

Act – Improving quality and customer satisfaction by responding to previously collected information.

|

Process Number |

Process Name |

Process Owner |

|

ACE/PR/01 |

Academic Year Planning |

Dr. Rekha Patil |

|

ACE/PR/02 |

Curriculum Design & Enrichment Process |

Prof.Naresh Sawant |

|

ACE/PR/03 |

Student Feedback and Grievances |

Mr Laxman Rajput, Prof. Vishakha Kamod |

|

ACE/PR/04 |

Admission Process |

Mrs.Smita Kulkarni |

|

ACE/PR/05 |

Preparation & Monitoring of Admin Calendar |

Mrs.Smita Kulkarni |

|

ACE/PR/06 |

Statutory requirement |

Mrs.Smita Kulkarni |

|

ACE/PR/07 |

Teaching and Learning Process |

Prof.Kavita Nevkar |

|

ACE/PR/08 |

Practicum (Preparation and Execution of lessons) |

Prof.Priyanka Morwal |

|

ACE/PR/09 |

Elite/Slow Learner Process |

Prof.Pravinkumar Jadhav |

|

ACE/PR/10 |

Concurrent Evaluation |

Prof.Shewta Varade |

|

ACE/PR/11 |

Conduction of University Viva Voce, Online & Theory Examination |

Prof.Pravinkumar Jadhav |

|

ACE/PR/12 |

Student Information System |

Mrs.Smita Kulkarni |

|

ACE/PR/13 |

Research, Innovation and Collaboration |

Dr.Rekha patil, Prof. Vishakha Kamod |

|

ACE/PR/14 |

Extension Activities & Collaboration |

Prof. Priya Kapadne, Prof. Naresh Sawant, Prof.Vishakha Kamod |

|

ACE/PR/15 |

Repair & Maintenance of Laboratory Equipment & Lab Management |

Mr.Kundan Dobade, Mr.Prashant Jadhav |

|

ACE/PR/16 |

Purchase & Receipt of Library |

Mr.Akshay Avhad |

|

ACE/PR/17 |

Library Membership, Book Circulation & Preservation |

Mr.Akshay Avhad |

|

ACE/PR/18 |

Student Facilities |

Mr Laxman Rajput |

|

ACE/PR/19 |

Scholarship to the students from various departments |

Mr Laxman Rajput |

|

ACE/PR/20 |

IT maintenance and management |

Mr.Pravin Salve |

|

ACE/PR/21 |

Maintenance Procedure, Work Environment & House Keeping & Security Management |

Mr.Mayur, Mr.Shyam Ingale |

|

ACE/PR/22 |

Co curricular activities & Student Achievement |

Prof.Kavita Nevkar, Prof. Manjusha Bhor |

|

ACE/PR/23 |

Training and Placement |

Prof.Prachi Chavan |

|

ACE/PR/24 |

Mentoring Program |

Prof.Kavita Nevkar |

|

ACE/PR/25 |

Alumni program |

Prof.Shital Aher |

|

ACE/PR/26 |

Monthly Report |

Prof.Smita Borade |

|

ACE/PR/27 |

IQAC |

Prof.Priya Kapadne, Prof. Bhagyashri Upasani |

|

ACE/PR/28 |

Great Teacher Characteristics |

Prof Vishakha Kamod |

Response:

ISO 9001: 2008 implementation

• Unit is ISO certified and all the activities are conducted as per prescribed in ISO regulations meticulously.

• In the introduction to ISO 9001, there is an explanation of the Process Approach and how important this is to implementing a Quality Management System that is compliant with the ISO 9001 requirements. In addition to this, there is a note about the methodology know as “Plan-Do-Check-Act” being applied to all processes.

Plan – Planning is one of the biggest parts of the QMS and starts with understanding the context of the organization and the needs of parties interested in the QMS, which is then used to define the scope of the QMS and the QMS processes. This is followed by the commitment of leadership in the company to drive the organization to a customer focus by defining the organizational roles and responsibilities and by establishing a quality policy to give the overall QMS a focus. The next level of planning is to identify and address risks and opportunities of the QMS, including setting and planning for quality objectives and changes to support continual improvement. The final level of planning is to identify and implement the support structure to allow you to carry out your plans. This includes resources, identifying competence, awareness, communication and to set the processes for creation and control of documented information.

Do – Planning is useless unless the plan is carried out. Controls need to be identified for the QMS operations, product or service requirements need to be identified, designs developed, controls placed on externally provided processes, products and services. The process of producing the product or service needs to be carried out with control of product and service release, any non-conforming products or services need to be addressed. In short, the activities of creating and providing products or services to the customers’ needs to be done.

Check – There are several requirements in the standard to check the processes of the Quality Management system to ensure they are functioning properly as they have been planned. There is a need to monitor, measure, analyse and evaluate the products or services to ensure they meet requirements, the processes used are adequate and effective, and customer satisfaction is being met. Internal Audit of the processes is the key way to assess the effectiveness of the system. Further is the Management Review process, which reviews and assesses all of the monitored data to make changes and plans to address the issues.

Act – Action in this case involves the actions needed to address any issues found in the check step. Improvement is the overall heading for these action steps with the activities of addressing nonconformity and Corrective Actions to eliminate the causes of actual or potential nonconformities as the first step in acting to improve the system.

ISO 9001:2015 Transformation

• needs to demonstrate its ability to consistently provide products and services that meet customer and applicable statutory and regulatory requirements, and

• aims to enhance customer satisfaction through the effective application of the system, including processes for improvement of the system and the assurance of conformity to customer and applicable statutory and regulatory requirements.

Reinforcing the culture of excellence:

• To Endeavour for excellence faculty are motivated for participation in workshops, Short Term Training Programs in various Institutes, Research work.

• Students are been provided to learn & study environment through Educational & Industrial visits.

• Various Internship opportunities are provided to students to gain practical based approach.

• Students are provided interaction with university toppers.

• 6 years of legacy of university Gold Medals in B.Sc.B.Ed and B.A.B.Ed.

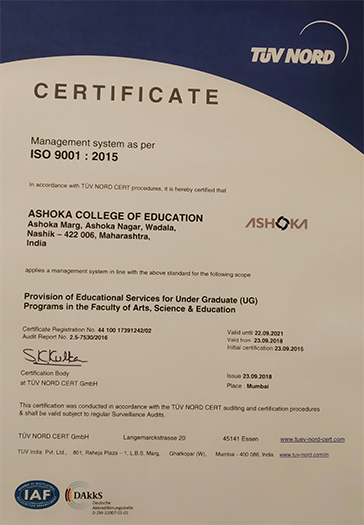

1. ISO Certification

|

Year |

AQARs prepared/ submitted.(Yes /No) |

Academic Administrative Audit (AAA) and initiation of follow up action |

Participation in NIRF.(Yes /No) |

ISO Certification.(Yes /No) |

NBA or any other certification received.(Yes /No) |

|

2017-18 |

No |

No |

No |

Yes |

No |

|

2018-19 |

No |

No |

No |

Yes |

No |

|

2019-20 |

No |

No |

No |

Yes |

No |

|

2020-21 |

No |

No |

No |

Yes |

No |

|

2021-22 |

No |

No |

No |

Yes |

No |